Price:

European delivery - 7-28 working days, other countries +7 working days.

Ask a question about this item

Ask a question about this item

Centrifugal smoke extraction fans CRMT ≤15930 m³/h

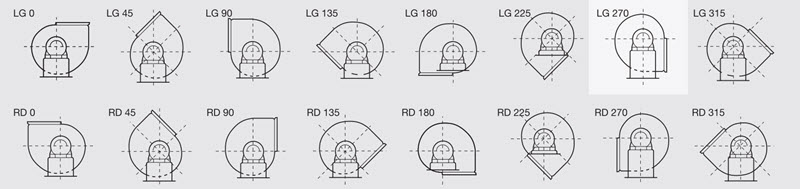

Standard product supplied with impeller housing position LG 90 (L2), different positions available on request

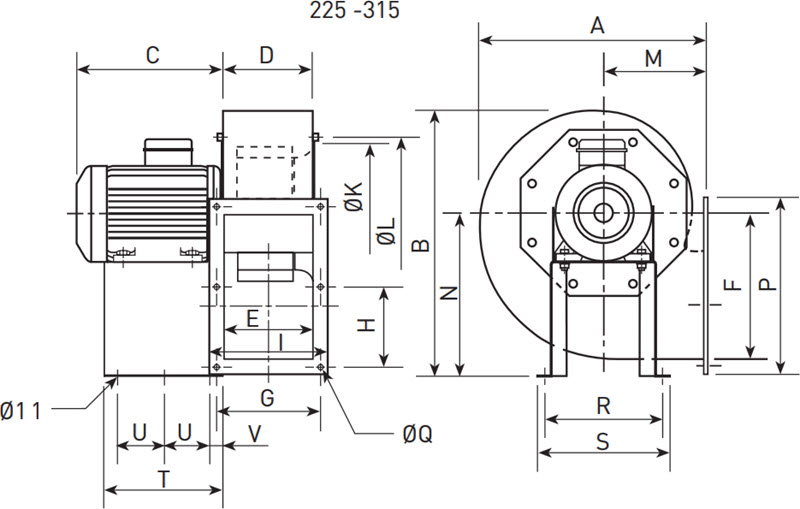

| Code CRMT |

A

|

B

|

C

max.

|

D

|

E

|

F | G | H | I | K | L | M | N | P | Q | R | S | T | U | V |

| 225/90 | 388 | 454 | 315 | 143 | 140 | 216 | 180 | 128 | 203 | 234 | 256 | 181 | 280 | 279 | 10.5 | 220 | 250 | 230 | 3x50 | 29 |

| 250/100 | 427 | 503 | 370 | 168 | 165 | 250 | 205 | 145 | 228 | 252 | 282 | 197 | 310 | 313 | 10.5 | 228 | 260 | 280 | 3x74 | 27 |

| 280/115 | 467 | 547 | 420 | 183 | 180 | 300 | 220 | 170 | 243 | 292 | 320 | 215 | 340 | 363 | 10.5 | 245 | 275 | 315 | 2x95 | 27 |

| 315/130 | 525 | 630 | 440 | 203 | 200 | 320 | 240 | 180 | 263 | 325 | 354 | 238 | 390 | 383 | 11 | 322 | 352 | 320 | 2x140 | 20 |

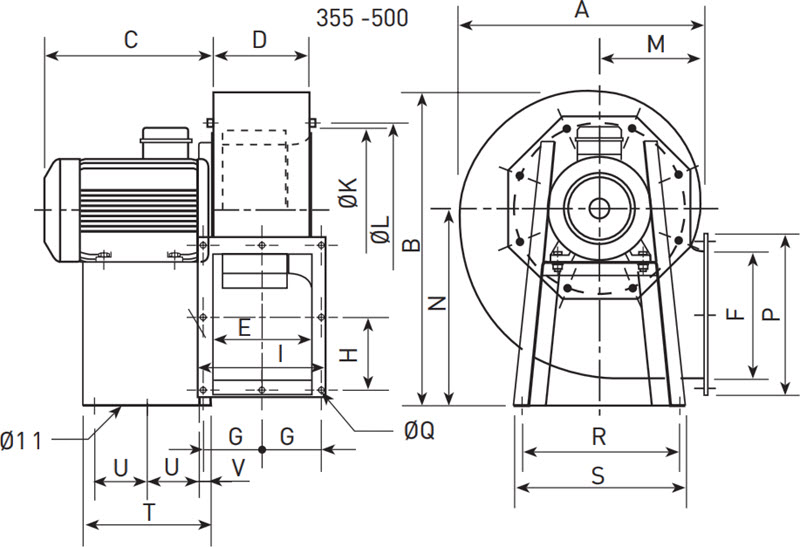

| 355/145 | 566 | 707 | 540 | 231 | 227 | 280 | 133 | 159 | 291 | 365 | 394 | 250 | 445 | 343 | 11 | 420 | 450 | 405 | 2x136.5 | 30 |

| 400/165 | 625 | 792 | 555 | 254 | 249 | 320 | 150 | 185 | 334 | 410 | 438 | 270 | 495 | 404 | 11 | 402 | 438 | 420 | 2x133x5 | 30 |

| 450/185 | 704 | 892 | 555 | 288 | 283 | 360 | 164 | 202 | 368 | 460 | 485 | 302 | 560 | 444 | 11 | 502 | 538 | 420 | 2x140 | 30 |

| 500/205 | 790 | 980 | 702 | 319 | 314 | 454 | 182.5 | 250 | 409 | 510 | 535 | 345 | 610 | 544 | 11 | 613 | 653 | 540 | 2x187.5 | 30 |

|

Code

CRMT

|

Poles | Speed, min-1 |

Power, W

|

Current, A

230 V

|

Current, A

400 V |

Capacity, m³/h

|

Noise level, dB(A)1.5m

|

Weight, kg |

| 4-225/90-0.55 | 4 | 1390 | 550 | 2.85 | 1.65 | 2350 | 70 | 23.5 |

| 4-250/100-1.1 | 4 | 1390 | 1100 | 4.8 | 2.8 | 3600 | 72 | 33 |

| 4-250/100-1.5 | 4 | 1400 | 1500 | 6.4 | 3.7 | 3900 | 73 | 36 |

| 4-280/115-2.2 | 4 | 1400 | 2200 | 9.1 | 5.3 | 5050 | 75 | 44.5 |

| 4-280/115-3 | 4 | 1400 | 3000 | 12.6 | 7.3 | 5500 | 76 | 47.5 |

| 4-315/130-2.2 | 4 | 1400 | 2200 | 9.1 | 5.3 | 5450 | 72 | 50.5 |

| 4-315/130-3 | 4 | 1400 | 3000 | 12.6 | 7.3 | 6400 | 75 | 53.5 |

| 4-315/130-4 | 4 | 1420 | 4000 | - | 9.3 | 7100 | 78 | 56.5 |

| 4-355/145-3 | 4 | 1400 | 3000 | 12.6 | 7.3 | 6200 | 75 | 55.5 |

| 4-355/145-4 | 4 | 1420 | 4000 | - | 9.3 | 7700 | 78 | 58.5 |

| 4-355/145-5.5 | 4 | 1440 | 5500 | - | 12 | 9300 | 81 | 71.5 |

| 4-355/145-7.5 | 4 | 1445 | 7500 | - | 15.5 | 10700 | 83 | 79.5 |

| 4-400/165-4 | 4 | 1420 | 4000 | - | 9.3 | 7200 | 77 | 73.5 |

| 4-400/165-5.5 | 4 | 1440 | 5500 | - | 12 | 8300 | 80 | 86.5 |

| 4-400/165-7.5 | 4 | 1445 | 7500 | - | 15.5 | 10460 | 83 | 94.5 |

| 4-450/185-5.5 | 4 | 1445 | 5500 | - | 12 | 7560 | 83 | 96.5 |

| 4-450/185-7.5 | 4 | 1445 | 7500 | - | 15.5 | 9900 | 86 | 104.5 |

| 4-500/205-7.5 | 4 | 1445 | 7500 | - | 15.5 | 8410 | 83 | 109.5 |

| 4-500/205-9.2 | 4 | 1450 | 9200 | - | 21.5 | 10300 | 85 | 121.5 |

| 4-500/205-11 | 4 | 1450 | 11000 | - | 22.5 | 11250 | 87 | 133.5 |

| 4-500/205-15 | 4 | 1460 | 15000 | - | 31 | 15930 | 89 | 148.5 |

| 6-355/145-1.5 | 6 | 945 | 1500 | - | 4.3 | 6700 | 75 | 54.5 |

| 6-400/165-2.2 | 6 | 950 | 2200 | - | 6.2 | 7750 | 72 | 73.5 |

| 6-450/185-2.2 | 6 | 950 | 2200 | - | 6.2 | 7800 | 75 | 83.5 |

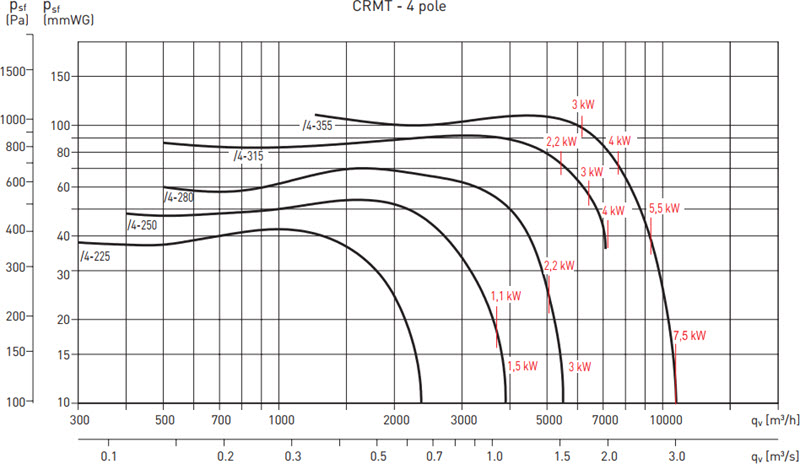

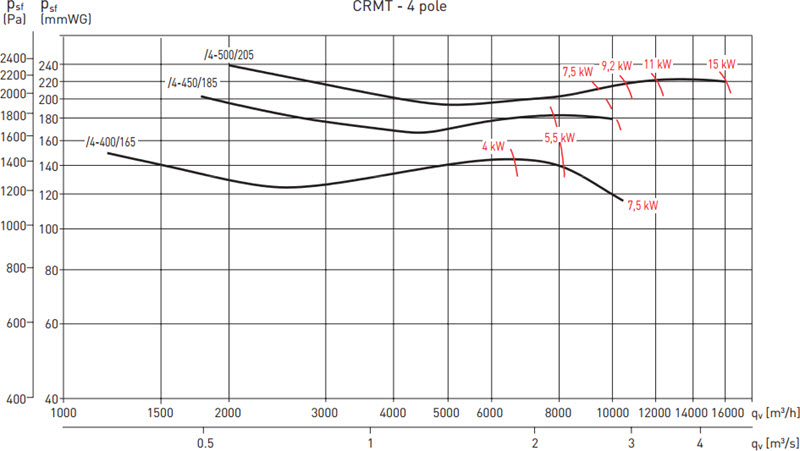

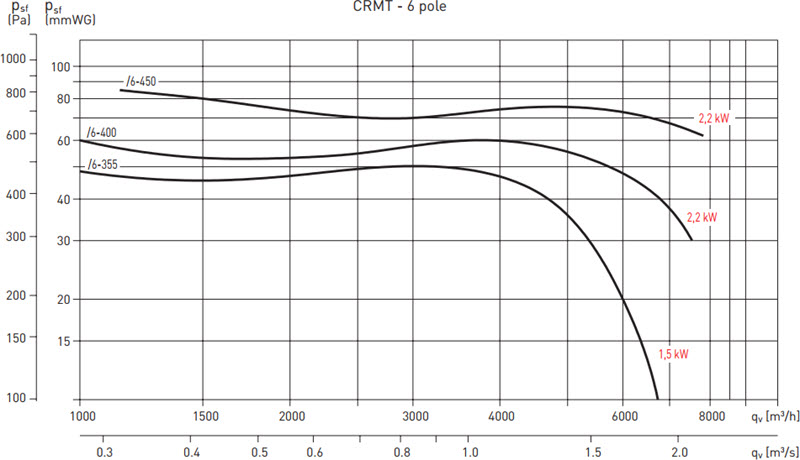

Pressure loss diagrams

You might also like: